Mbsm.tn, Parts, of a Centrifugal, Pump

Category: Machine Learning

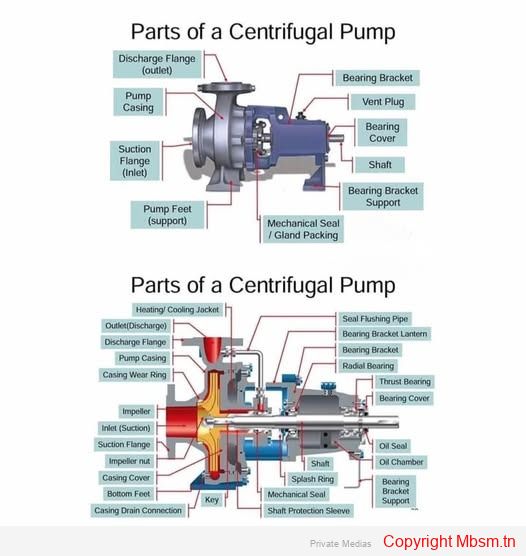

Centrifugal pumps are widely used devices for moving fluids, and they consist of several critical components that work together to perform this function. Here are the main parts of a centrifugal pump:

Key Components of a Centrifugal Pump

- Casing (Volute):

- The casing, also known as the volute, is the outer shell that houses the pump components. It contains the liquid being pumped and converts kinetic energy into pressure by slowing down the fluid as it exits the impeller. The design can be either single-piece or split into upper and lower sections, depending on the pump’s configuration14.

- Impeller:

- The impeller is the rotating component responsible for imparting energy to the fluid, increasing its velocity and pressure. It consists of blades or vanes that push the liquid outward from the center to the periphery as it rotates25. Impellers can be categorized into three types: open, semi-open, and closed, each suited for different applications1.

- Shaft:

- Bearings:

- Mechanical Seals:

- Suction and Discharge Ports:

- Backplate:

- The backplate acts as a seal for the impeller, providing structural support and helping to maintain pressure within the casing1.

- Diffuser (optional):

- Suction Pipe and Foot Valve:

- The suction pipe allows fluid to enter the pump from a source, while a foot valve can prevent backflow when the pump is not in operation3.

- Discharge Pipe and Valve:

- These components channel the pumped fluid away from the pump to its destination while controlling flow rates and pressure3.

Understanding these components is crucial for anyone involved in selecting, operating, or maintaining centrifugal pumps, as each part plays a vital role in ensuring efficient performance and reliability in fluid transport applications.