File Pdf, Mbsm.pro, Compressor, Lg, Lbp, MB88NA, 151 w, 1/5 hp, r600a, 1ph-220v-50hz

Mbsm-tn-private-media_-comprehensive-guide-to-siberia-compressors-specifications-performance-and-applications

Pdf File, Mbsm.pro, Compressor, BTF60AA, 1/7 hp, r600a, lbp, Serbian Compressor, serie T, from 180 L to 200 L, from 70 to 75 W

Mbsm-tn-private-media_---comprehensive-guide-to-siberia-compressors-specifications-performance-and-applications

https://mbsm.tn/wp-content/uploads/2025/03/Mbsm-tn-private-media_-comprehensive-guide-to-siberia-compressors-specifications-performance-and-applications.pdf

Mbsm-tn-private-media_mbsm.pro-Mbsmpro Compressor BTF60AA 17 hp r600a lbp Serbian Compressor serie T from 180 L to 200 L from 70 to

https://mbsm.tn/wp-content/uploads/2025/03/Mbsm-tn-private-media_-comprehensive-guide-to-siberia-compressors-specifications-performance-and-applications.pdf

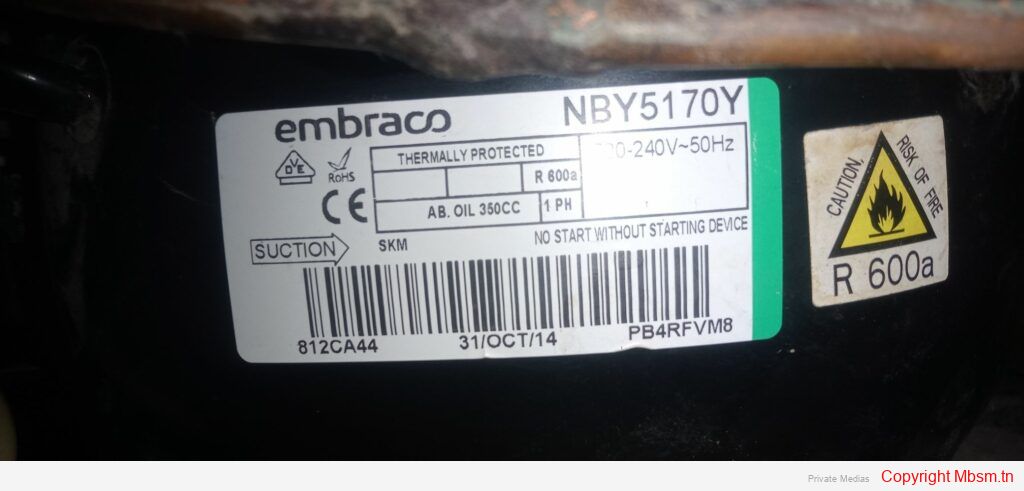

Refrigeration compressors are essential components in cooling systems, and understanding common issues can help in troubleshooting and maintaining their efficiency. Below are some prevalent problems, their causes, and potential solutions.

Regular maintenance and prompt troubleshooting of these common issues can significantly enhance the lifespan and efficiency of refrigeration compressors. Implementing a preventive maintenance schedule will help mitigate many of these problems before they escalate into major repairs.

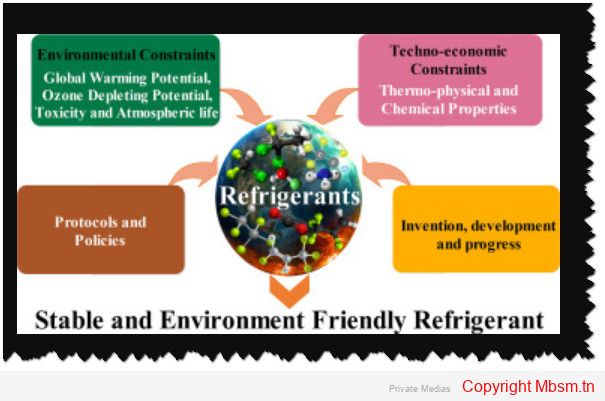

Refrigerants play a crucial role in the efficiency of cooling systems, particularly in vapor compression refrigeration cycles. This analysis focuses on two commonly used refrigerants: R134A (tetrafluoroethane) and R600A (isobutane). Both refrigerants have distinct properties that influence their performance in various applications, including air conditioning and refrigeration.Cooling Capacity and Coefficient of Performance (COP)

Thermophysical Properties

Environmental Impact

Applications and Trends

In conclusion, both R134A and R600A have unique advantages and limitations that affect their performance in cooling systems. While R134A offers higher efficiency and cooling capacity, R600A presents a more environmentally friendly option with specific safety considerations. The choice between these refrigerants will increasingly depend on balancing performance needs with environmental responsibilities.

Understanding the Differences Between R134A and R600A in Refrigeration Systems

In the realm of refrigeration, selecting the right refrigerant is crucial for efficiency, environmental impact, and safety. Two commonly used refrigerants are R134A and R600A, each with distinct properties and applications. This article delves into their differences, advantages, and disadvantages to help you make informed decisions in refrigeration systems.

In summary, while both R134A and R600A serve vital roles in refrigeration systems, their differences are significant. R600A offers higher efficiency and a much lower environmental impact but comes with flammability risks that must be managed. Conversely, R134A provides a safer profile but at the cost of higher energy consumption and greater environmental concerns.As industries continue to shift towards sustainable practices, understanding these differences will be essential for choosing the right refrigerant for specific applications. This article provides an overview of the key differences between R134A and R600A in refrigeration systems, highlighting their chemical properties, efficiency, environmental impact, safety considerations, and applications.